- Tel: 0086-21-53021748

- E-mail: export@shdreamax.com

-

Three Effect Sewage Air Valve (TES)

Size range: NPS 2"~8"

Threaded: NPS 1"~2"

Pressure ratings: 150LB / 300LB / PN16

Working temperature:-29℃~ +150℃.

Suitable Medium: Slurry / Sea Water/ Sewage

Body Material: ASTM A216 WCB SS304 / A351 CF8 SS316 / A351 CF8M SS316L / A351 CF3M

Trim Material:A276 SS316L

Seat 1: PTFE

Seat 2: Viton

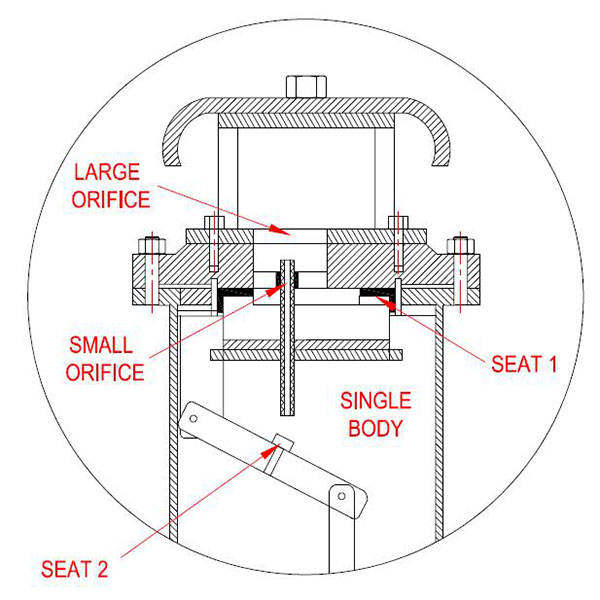

The latest state of the art Slurry/Sewage Air Valve design: A Single Body, Double Orifice “Gamma HP Slurry/Sewage Air Valve”.

A new generation of Air Valve Design. Field tested under actual operating conditions. Incorporating all features that have made the FOX Air Valve and Delta HP Air Valve the world’s finest…Now in a Single Body-plus with two independent orifices - to give even greater performance and reliability.

You no longer need to dig deeper trenches or build deeper vaults because the Gamma HP model is at least 30% shorter than other equivalent Slurry/Sewage Air Valve models!

Air Valve that won’t spill or spurt before shutting off. no more messy waste flooded valve vaults to pump out…or pump station floors to mop up…it shuts off drop tight.

Take a serious look at - Gamma HP Slurry/Sewage Air Valve.

Manufactured to our industry’s highest standards providing the highest efficiency and reliability of any sewage air valve available in the market today.

Gamma HP Air Valve are specially designed for use with Slurry/Sewage and Waste media. The float Stem and Body keep the valve Venting Mechanism as free from contact with the sewage as possible. The float hangs freely in the valve body and responds instantaneously to the fall and rise of the sewage media due

to the float.

1. With two independent orifices.

- 1.) Large orifice.

- For air out and in (Air/Vacuum Valve function)

- 2.) Small orifice

- For air release (Under pressure function)

- Gamma HP Air Valve (Single Body, Double Orifice) to allow large volumes of air to escape or enter through the larger diameter orifice when filling or draining a pipeline.

- When the pipeline is filled and pressurized the large air/vacuum

- orifice shall stay closed, but the smaller diameter air release orifice shall remain operative and open to allow small pockets of air accumulation to escape automatically and independently of the large orifice.

- The large air/vacuum orifice shall shut off when the free floating-center guided plug is raised into the orifice by the lifting force of the float. The large orifice shut-off shall be “Without Spilling”.

2.The Viton seat 2 must be fastened to the valve cover, without distortion, for drop-tight shut-off.

3.Without Spilling.

People easily tolerate and are reasonable about water spillage from valves but sewage…that “nasty stuff” is cause for some Engineers and Users alike to avoid use of Sewage Air Valves, regardless of need to a system.

During the past 30 years, the single most highly objectional complaint about the Sewage Air Valve is, “it spills” or “it spurts sewage”!. The Gamma HP Air Valve float eliminates this complaint because of the unique Impact Zone extremely sensitive to sewage media entering the Sewage Air Valve. The impact zone causes instantaneous and upward movement of the float to shut-off the discharge orifice as soon as media contacts the float. Now, no spilling or spurting occurs even with low pressure (below 20 psi).

4.Suitable for extreme conditions: Slurry pipelines, waterlines, sewage. etc

5.Coating suitable for highly aggressive environments(Epoxy).

6.Full bore design to prevent clogging.

7.Reduces pressure drop.

8.Trim(Float, Stem, Hinge) is non-corrosive stainless steel A276 SS316L

9. Can be microscale venting.

10. Convenient maintenance.

11. Anti-water hammer.

2.Height dimension (H) standard as to: MFR-STD

3.Flange dimension conforms as to: ASME B16.5 / BS EN 1092

Threaded Standard as to: NPT : ASME B1.20.1 BSP : ISO 7-2: 2000

4.Testing And Inspection as to: API 598

5.Pressure-temperature conforms as to: ASME B16.34

6.Anti Corrosion as per NACE MR-0175(2002) requirement

- Air Release Valves

- Three Functions Air Valve/ Combination Air Release Valve (FOX)

- Wastewater Air Valve/ Combination Sewage Air Valve (Gamm HP)

- High Anticorrosive Air Valve/ Combination Inner Lined Air Valve

- Two Functions Air Valve/ Air Release Valve(Omega)

- Two Functions Air Valve/ Inner Lined Sewage Air Valve(Omega HP)

- Combination Lined Sewage Air Valve (Delta HP)

- Micro-Air Release Valve/Automatic air release valve (A200)

- Pressure Reducing Valves

- Ball Valves

- Butterfly Valves

- Strainers

- Check Valves

- Pinch Valves

- Diaphragm Valves

- Knife Gate Valves

- Safety Valves

- Steam Traps